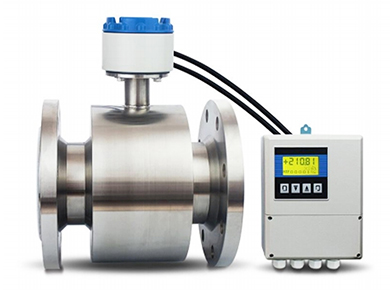

Electromagnetic flow meter, also known as magnetic flow meter, mag meter, is a kind of based on Faraday’s law of electromagnetic induction to measure the volume flow of conductive liquid meter. It is characterized by unobstructed measurement and small pressure loss, and is suitable for corrosive media such as acids, alkalis, salts and slurries.

Faraday’s law of electromagnetic induction, it is used to measure the volume flow of a conducting liquid.

How does electromagnetic flowmeter work?

Core Principle: Faraday’s Law of Electromagnetic Induction

- Faraday’s Law of Electromagnetic Induction states that when an electrically conductive body moves in a magnetic field, an induced electromotive force (voltage) is generated within the conductive body.

- Electromagnetic flow meters utilize this principle to measure the flow of conductive fluids.

Work process

- Magnetic field generation:

- Electromagnetic flowmeter inside the electromagnetic coil to generate a stable magnetic field, the magnetic field perpendicular to the direction of fluid flow.

- Fluid flow:

- Conductive fluids (such as water, sewage, acid and alkali solutions, etc.) flowing through the magnetic field area.

- As the fluid is electrically conductive, its flow is equivalent to the movement of conductive bodies in the magnetic field.

- Induction electromotive force generation:

- According to Faraday’s law of electromagnetic induction, the motion of the fluid in the direction perpendicular to the magnetic lines of force and the direction of flow of the fluid to produce induced electromotive force.

- The magnitude of the induced electromotive force is directly proportional to the flow rate of the fluid.

- Signal Detection:

- Electrodes located on both sides of the pipe detect the induced electromotive force generated.

- Signal processing and display:

- The detected induced electromotive force signal is amplified and processed, converted into an electrical signal proportional to the flow rate.

- The meter display shows the flow rate value.

Advantages

- No pressure loss: No obstructions in the measuring tube, no additional pressure loss.

- Unaffected by fluid properties: Measurement results are unaffected by fluid parameters such as temperature, pressure, density and viscosity.

- Wide measuring range: Low and high velocity fluids can be measured.

- High reliability: No mechanical moving parts, reducing wear and tear.

Applications

Electromagnetic flowmeter is mainly used to measure the flow of various conductive liquids, widely used in water treatment, chemical, food and beverage, pharmaceutical, pulp and paper, mining, electric power, HVAC and many other industries. The characteristics of unobstructed measurement, low pressure loss and the ability to measure corrosive and slurry materials are the key reasons for its wide application.